Using Drones and Software to Support Warranty Inspections

Aerial PV system inspections can be used for a variety of applications and reasons. The purpose of this blog post is to discuss the benefits of using drones and Raptor Maps for the inspections of sites for warranty reasons. Regular inspections of a PV system are a common part of asset management and O&M and need to be done regularly to maintain the validity of the warranty. Regular inspections also create data sets and reference points for future inspections, helping you identify the time period in which the problem started.

In our experience across more than 25GW of PV inspections, there are 3 common options used for PV system inspections. Option A, Human labor consisting of field walks and visually identifying warrantable issues, option B, manned aircraft (airplane) inspection of a PV system, or option C, the use of drone technology to perform the inspection. Unless your solar PV system is extremely small and can be thoroughly walked and visually checked in a couple of hours, we have found that using a drone is the most efficient, cheapest, and quickest method. The capabilities of even an entry-level industrial drone reduce the inspection process time, and the amount of time it takes until you receive your report.

With I-V curve tracing, PV system inspections require:

1 MWp = Multiple days

100 MWp = Multiple Weeks

With a thermal drone, PV system inspections require:

1 MWp = Less than 1 hour

100 MWp = 2 days

Application in Warranty Inspections

For warranty inspections that require a thorough review of every module on a PV system, aerial inspections by drone are completed in a fraction of the time when compared against human labor. The inspection and, which normally takes weeks, will take a drone a day or two (for commercial-scale and utility-scale systems. Once all imagery/data of the site has been collected with the drone, the data analysis and the creation of a detailed, clear, and actionable report with Raptor Maps can be completed in days. The process to identify modules with the warrantable issue is 1000 times faster. Instead of spending valuable time and labor on the inspection to find anomalies, you can spend this time on investigating the problems in more detail and laying out your warranty claim.

Drones have a wide capability of what can be found. They’re able to detect:

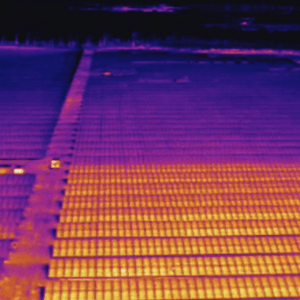

Large scale issues.

Inverter Anomaly Identified on Solar PV Plant.

Module defects.

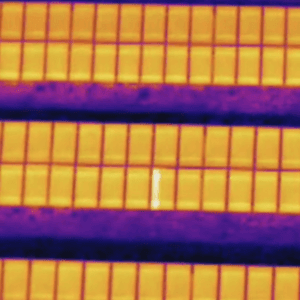

One of many diodes identified during a warranty inspection.

Cell level anomalies.

Cell level anomalies are easily identified with thermal cameras.

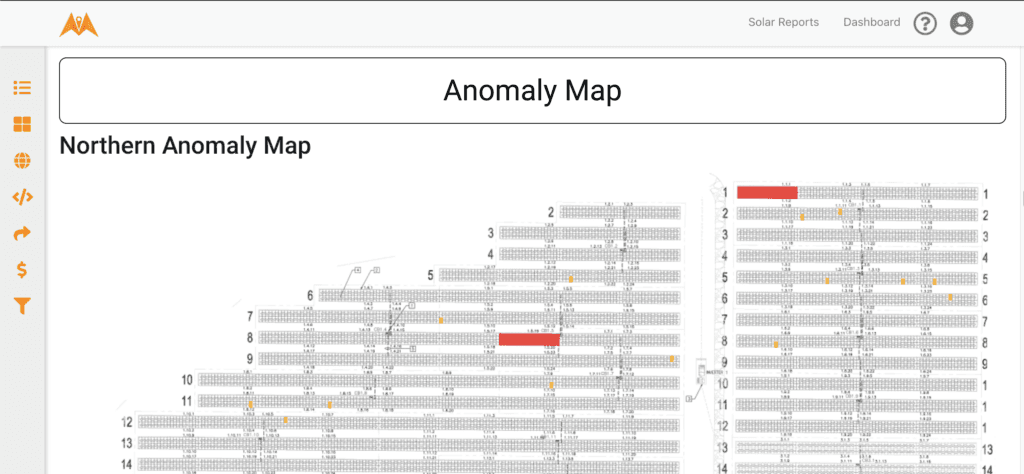

If it can be identified visually, a drone will be able to find the problem. The Raptor Maps built report, will localize, and prioritize the defect so you know the severity of issues that are affecting your solar PV site.

Image from a Raptor Maps report showing affected modules, and their location and severity.

Drones and Software Benefits

For anomalies that require thermography and can’t be seen by the eye, drones deliver the capability to detect thermal anomalies and accurate temperature deltas of those anomalies. This information enables you to know which modules are functioning correctly, and which are not functioning correctly. The data collected with a thermal drone also enables you to identify where the anomaly is located in the PV system down to the module level. When following the IEC standards for aerial thermography of a PV system, capturing the data at 3cm/px enables very specific detail to be reported on, and gives the warranty claims a stronger foundation as well. The thermal image resolution is critical for the accuracy of the findings. Using a manned aircraft/plane cannot deliver this high-level resolution and detail in thermal image resolution.

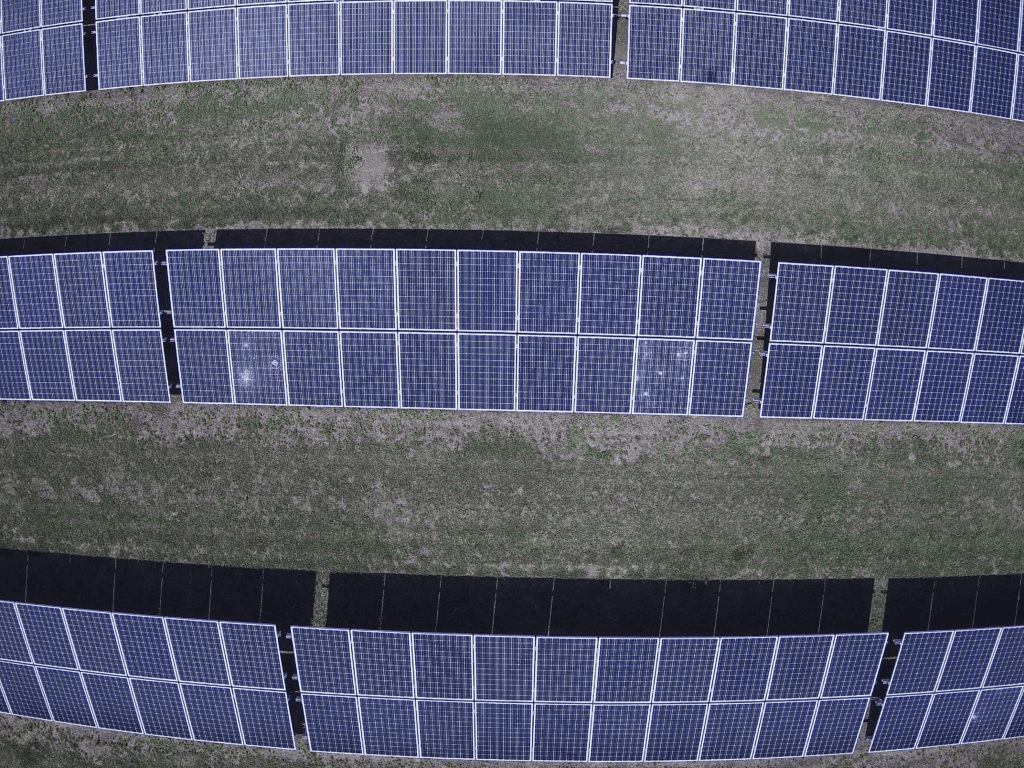

High-resolution image of a solar PV system flown at 1cm/px GSD showing module cracking.

Inspection Standardization

Inspections are also standardized when using a drone and data analysis software like Raptor Maps for your warranty inspections. We have strict data requirements for acceptable imagery. You’ll receive the same level of quality in each inspection analyzed through this process. Standardizing the inspection will allow you to build a database of more in-depth reference points, and create a higher level of certainty of correct anomalies because all inspections were performed and analyzed the same way, each time.

When every aerial inspection of a PV system is performed the same standardized way and all data is reviewed by the same tool such as Raptor Maps, you are able to find recurring issues. This also enables you to take note of anomaly trends and further diagnose root causes including issues that could be due to a manufacturer defect or installation error. Properly identifying the root cause with standardized data and reports enables you to file a warranty claim and replace the component instead of constantly addressing the same problems and increasing labor onsite.

We have heard from several companies that own, manage, and maintain solar assets that the need for regular inspections up O&M costs. PV systems built with components that have known issues and require these regular inspections to catch new warrantable issues consumes significant time and labor bandwidth. Though the costs can be calculated and possibly budgeted for, using drones for these ongoing inspections and a credible software solution will reduce the amount of labor required. However, drones combat this and allow for time to be spent on other matters, and/or further investigating or field addressing the anomalies.

Conclusion

In close, applying drones and software technology is an easier, less expensive, and more efficient way to inspect your solar PV system for warranties. The accuracy of the thermal cameras allows you to identify anomalies and track trends to build a robust case for the warranty claims.

If you want a more in-depth breakdown of thermal drones application in solar inspections, check out our free 5-part webinar series created with FLIR!

If you would like to learn more about how using drones and software can support solar inspections for warranties please contact us HERE or email us directly through info@raptormaps.com. We can also help you learn more about our software that converts your inspection imagery into final reports that are accurate and easy to use for asset management and maintenance.

Next steps

From the civil engineering on your site down to the wiring on the back of your panels, the Raptor Solar platform provides you detailed, up-to-date data on the conditions and performance of your solar fleet so that your team has the intel they need to do their jobs effectively, quickly, and safely.