Posted On 3/22/18

In partnership with FLIR Systems, the world’s largest supplier of thermal imaging technology, Raptor Maps recently hosted a webinar to cover the basics of inspecting solar farms with drones. With 1,500 registered viewers, we reached an unprecedented audience interested in applying this technology to detect issues and optimize asset management.

The entire webinar can be viewed below for anyone who was unable to tune in live. The following is a summary of the central themes discussed in the webinar. Part 2, a recap of the most frequently asked questions during the webinar, can be found here.

Commercial Drone Operations for Solar Farm Inspections

Drones are more accessible than ever before, and the market for thermal imaging is rapidly expanding. A remote pilot certificate can now be earned through a knowledge test, and the drone/camera hardware has become more integrated and user-friendly. As the photovoltaic (PV) solar industry experiences double-digit annual growth, drones have become an effective and efficient means to analyze PV assets ranging from utility-scale power plants to community and industrial installations. The majority of operations and maintenance (O&M) companies are either flying drones themselves or contracting drone services, and asset owners are also realizing the benefits.

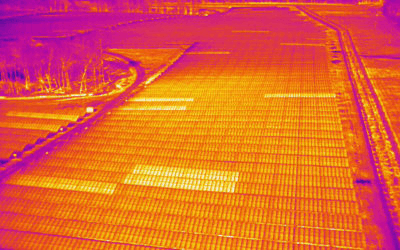

Value of Thermal Imaging in PV System (Solar Farm) Inspections

Aerial thermal imaging detects PV system anomalies from the inverter (large) level down to the string, module (panel), and cell levels. When areas in the PV system are defective, the energy from the sun is not converted into electrical energy, resulting in an increase in temperature. Additionally, changes in the surface properties of a module manifest as a difference in emissivity, which is detected with a thermal camera. The results of aerial thermal imaging inform asset management, and save 2–5 times the labor cost in the field. Every single module is analyzed, and site condition is quantitatively tracked over time.

Planning Inspections

It is important to know the purpose of the PV system inspection and understand the level of detail a client needs prior to data collection. You should also check to see if there is satellite imagery of the PV system; if not, plan on capturing color (RGB) images to for an orthomosaic. Even if there is satellite imagery, color (RGB) images improve the quality of the report. Make sure to note the module technology (e.g., polycrystalline, CeTe), wiring (e.g., number of modules per string), and other pertinent information.

Collecting High-Quality Data

Fly on a sunny day, and avoid glare and motion blur. Take radiometric images with your thermal camera, as well as a color (RGB) dataset.We recommend high overlap (in the direction of flight). Low sidelap (between passes) is acceptable, as this will save a considerable amount of time in the field. Fly either parallel or perpendicular to the rows (not diagonally). A high-altitude site overview is helpful for detecting larger issues. Ensure your images contain metadata (GPS, altitude, timestamp, etc.). Verify your data before leaving the site.

Creating Valuable Deliverables

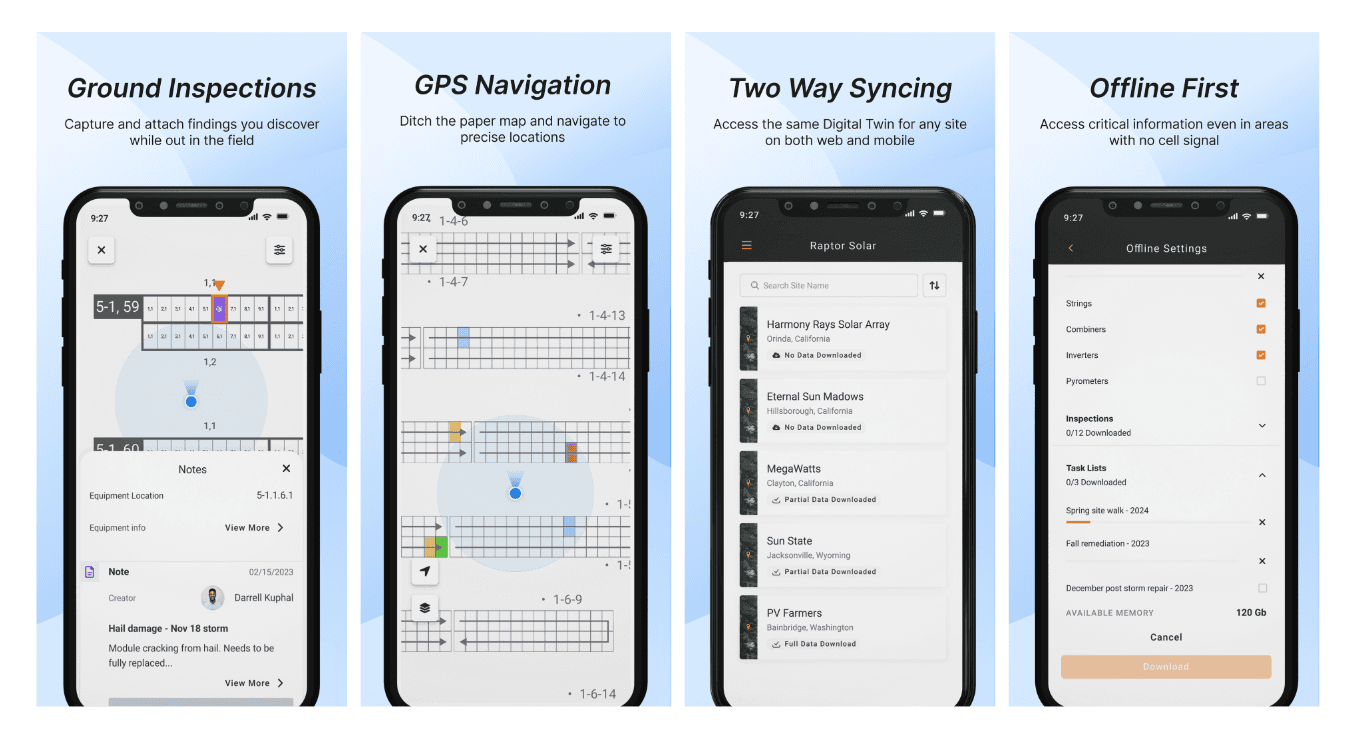

Raptor Solar deliverables are optimized for asset owners, performance managers, field technicians, and other solar professionals. Managers need summary statistics, grouped logically, and analysis to facilitate decision-making. Technicians need to quickly and accurately locate an identified module. Deliverables should integrate into the existing workflow. The client should be able to security share the results with their customers and within their own organization to participate in the decision-making process. Changes to the site should be quantitatively tracked over time.

Contact us

Raptor Maps is building the digital foundation for a more resilient and scalable solar. From construction to end-of-life, we are your long-term software partners to ensure your sites are operating as expected and producing reliable energy to support the energy transition.