An asset owner of a large utility-scale portfolio was facing significant underperformance and O&M challenges at a 150 MWdc site in ERCOT. In particular, escalating DC health issues were driving power production and revenue far below modeled expectations.

Solution & Approach

The asset owner implemented Raptor Solar Sentry to give them a direct view into the conditions and health of the underperforming asset, arming them with the insights needed to drive effective prioritization and accountability with their O&M provider. They deployed Sentry through a two-pronged program:

Routine inspection schedule focused on DC health and substation thermal anomalies

On-demand missions, such as to respond to events or conduct root cause analysis

Sentry’s findings also empowered the O&M team with better data and insights to support safe and efficient remediation, with technicians using the Raptor Maps Mobile App to navigate to task locations and access Sentry’s findings through a map-based interface.

The Result: $2M in recovered Revenue

Ultimately, the asset owner used the automation and insights provided by Sentry to drive a 75% decrease in underperformance within 12 months of deploying Sentry, resulting in $2M in recovered annualized revenue. Sentry continues to provide them with a source of ground truth to ensure asset performance improvements stay on-track and emergent risks are appropriately triaged.

Use Case: Routine DC Health Inspections

The asset owner leveraged Sentry’s DC health inspections to routinely track and verify remediation, as well as monitoring for persisting and emerging anomalies. The data collected served as an objective, dynamic source of truth on DC health over time— supporting both the asset owner and the O&M team. Initially, combiner, inverter-level, and tracker anomalies were the primary drivers of DC capacity loss. As inspections continued, they revealed an evolving set of issues, including a spike in string outages. The quarterly inspections armed the O&M with up-to-date, GPS-precise insights to guide corrective maintenance.

Use Case: Ground Fault Root Cause Analysis

Several blocks were experiencing persistent ground faults causing inverter failures, occurring multiple times per week. Sentry conducted targeted root cause analysis inspections and discovered that cracked modules were at the heart of these faults. Focused, block-by-block inspections ultimately identified and facilitated the successful replacement of more than 600 cracked modules, resolving the issue.

Other Use Cases: Erosion, Substation, and Livestream

Erosion /Drainage Monitoring

Erosion and water management challenges were creating safety hazards and blocking access to critical areas, preventing remediation of high-priority issues such as downed inverter blocks. The asset owner activated Sentry to track the progress of erosion remediation efforts, using clear visual documentation within a map-based Digital Twin to ensure safe and timely corrective maintenance.

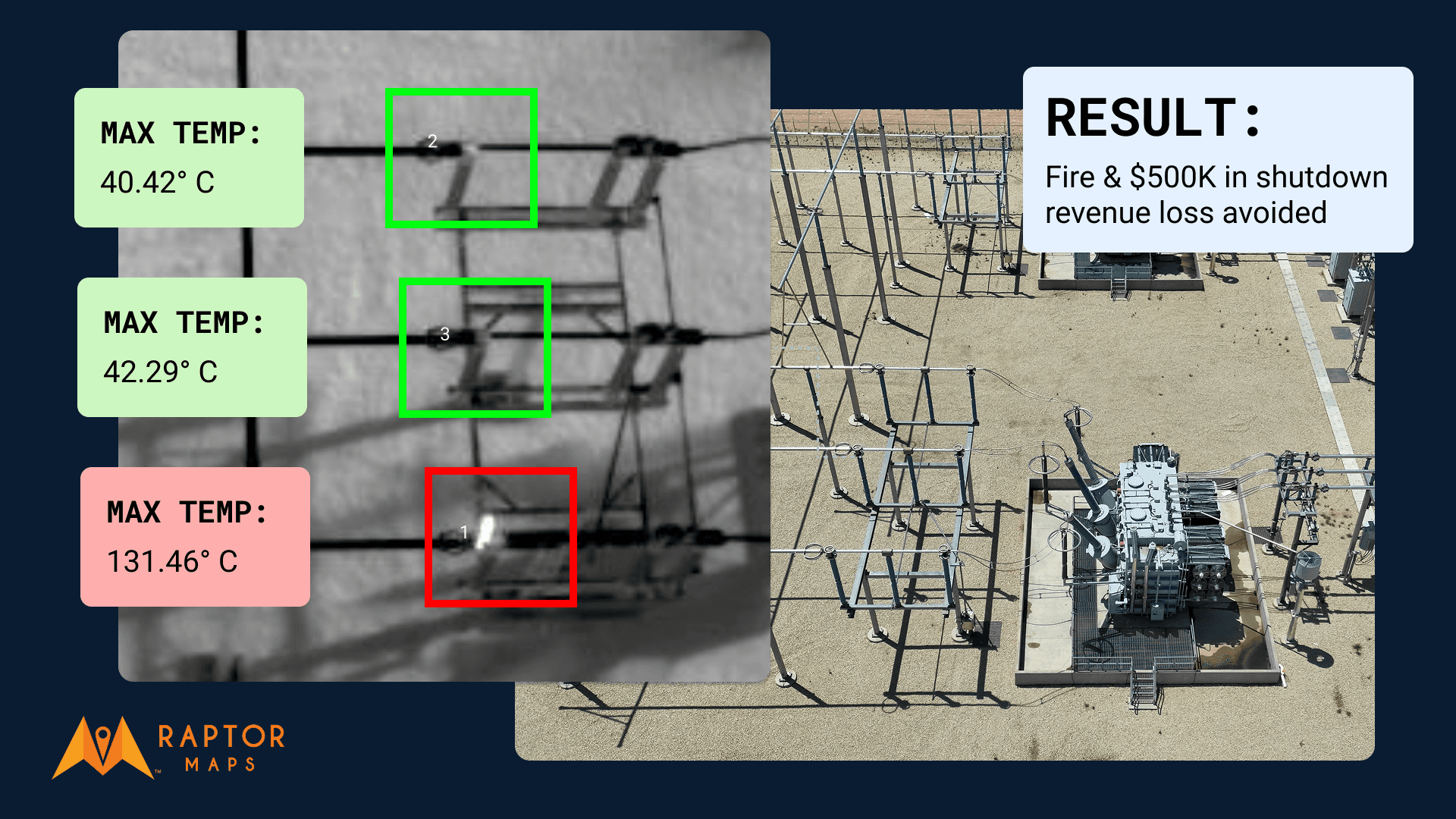

Routine Substation Inspections

The site’s substation had historically only been inspected once per year. The asset owner used Sentry to conduct monthly inspections, enabling proactive risk management. Sentry detects thermal anomalies that, if left unaddressed, could have escalated to fires or full substation failures. This visibility enables proactive maintenance before the anomaly escalates.

Rapid Response & Livestream

Sentry’s on-demand missions gave the asset owner the ability to quickly gain direct, ground-level visibility following alerts or events, such as severe weather events. These rapid-response missions enabled faster, better-informed decision-making during critical moments.

Next steps

From the civil engineering on your site down to the wiring on the back of your panels, the Raptor Solar platform provides you detailed, up-to-date data on the conditions and performance of your solar fleet so that your team has the intel they need to do their jobs effectively, quickly, and safely.