As substations are single points of failure for power delivery, catching issues before they escalate is critical. However, substations on utility-scale solar sites are inspected on various cadences and with varying degrees of rigor. By leveraging Raptor Solar Sentry's remote inspection capabilities, owners and operators are conducting routine inspections to augment their substation maintenance program. Here’s how one IPP prevented $500K+ in revenue loss by catching an issue for immediate remediation before the issue caused a fire and substation shutdown.

A Two-Pronged Strategy

An independent power producer with Raptor Solar Sentry drone-in-a-box units docked on multiple sites implemented a two-pronged program to leverage autonomous remote inspections delivered through Sentry.

Pre-scheduled, routine inspections that proactively identified issues across equipment, environment, and infrastructure over time. The results are used to align on priority items with their O&M

On-demand inspections to respond to alerts and events (such as severe weather), to triage damage, verify remediation, and conduct root cause analysis

In addition to a comprehensive annual substation inspection led by their field team, the IPP set up a monthly cadence for substation inspections in their Sentry inspection calendar. The program enables them to monitor for and remediate any failure potentials before they escalate to more costly shutdowns.

What Sentry Found

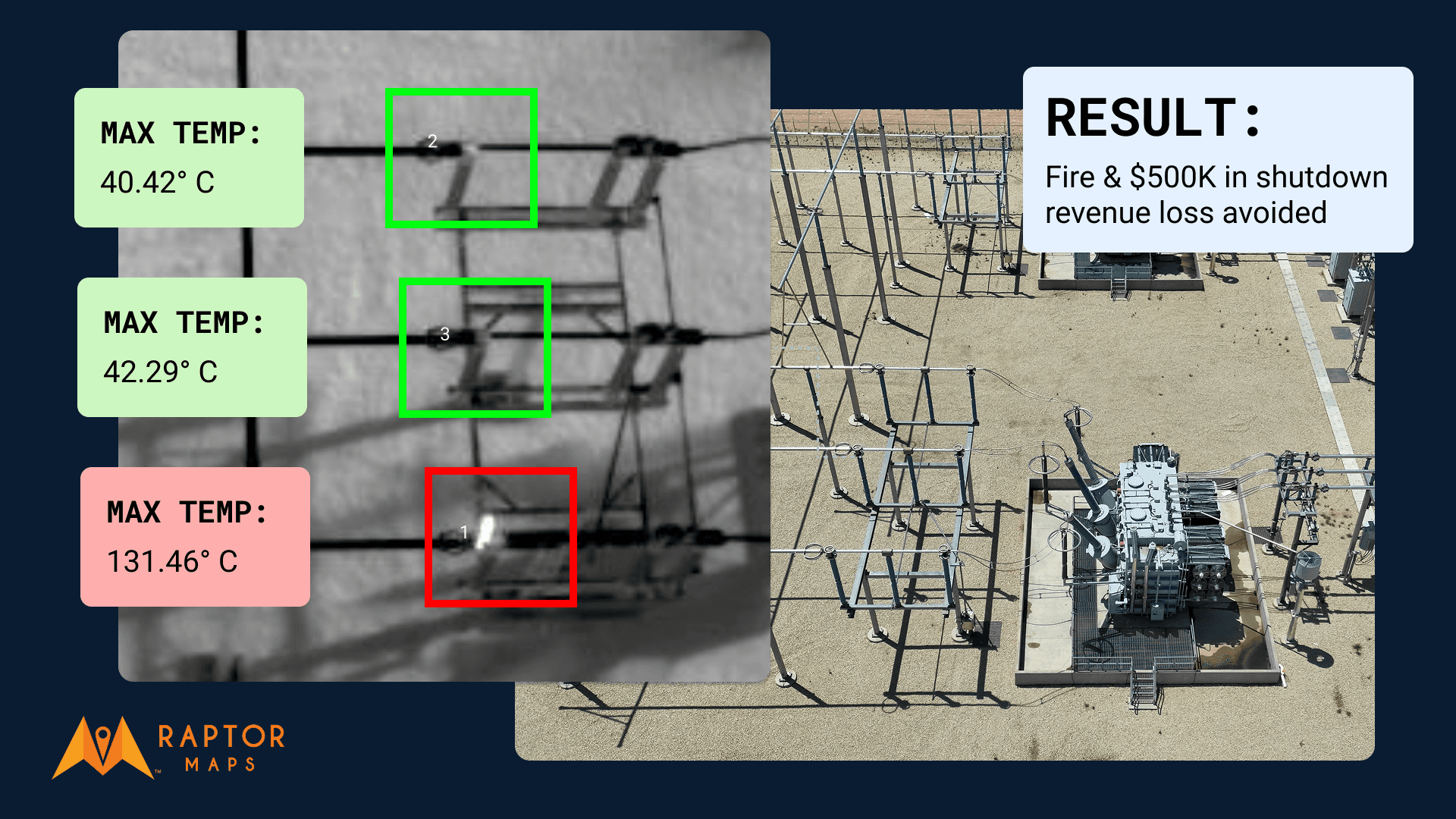

On one of their sites, the monthly substation inspection program revealed the emergence of a thermal anomaly with a temperature delta of nearly 100°C on one of the switches that did not appear in the previous month’s inspection.

After receiving the results, the IPP deployed Sentry immediately to collect more data to investigate the anomaly. The on-demand inspection found that two main switches were not properly closed, with improper blade seating as a result of the switch handles not being fully rotated during the last operation.

How the IPP Responded

In order to prevent a fire and equipment failure, the IPP immediately notified the site team to shutdown the substation and initiate remediation. Moreover, the data from Sentry armed the O&M team with detailed location and anomaly information to enable safe and effective remediation.

By remediating before the issue escalated to a costly site shutdown that would have lasted a couple of weeks, the IPP was able to avoid $500K in revenue loss and fix the issue before it caused further damage. While remediation was underway, the IPP launched daily Sentry missions to track remediation status and verify that identified issues were successfully resolved.

The IPP was able to accelerate decision making and resolution using Sentry’s remote inspection capabilities and ability to launch on-demand. The data collected by Sentry also inform more productive conversations across internal and external stakeholders by providing a shared, visual source of truth. After the verification of successful remediation, Sentry’s inspection calendar on this site returned to its steady state of pre-scheduled routine inspections.

Next steps

From the civil engineering on your site down to the wiring on the back of your panels, the Raptor Solar platform provides you detailed, up-to-date data on the conditions and performance of your solar fleet so that your team has the intel they need to do their jobs effectively, quickly, and safely.