Our autonomous drone solution, Raptor Solar Sentry, has responded to numerous fires on the more than 12GW of assets that Sentry is deployed on. On one utility-scale asset protected by Sentry, we observed 3 fires on-site in the last 6 months alone. Managing fire risk is made more challenging due its various causes, ranging from environmental to equipment-driven. That is why we are excited to introduce our newest Inspection type, Fire Watch.

Fire Watch builds upon a number of existing inspections that help manage risk already offered by Raptor Maps – Back of Panel Wiring, Cracking and Vegetation inspections to name a few – and creates a protocol in which autonomous drones can serve as ‘first responders’ to fires on site, in addition to more consistent preventative monitoring during periods of higher fire risk.

Over the past few years, we observed that a number of our partners were already using our technology to gain decisive edges in gathering critical intelligence on fire risk and prevention, and the Firewatch inspection formalizes this into a distinct offering.

Read on to learn more about how this inspection works and why it represents a critical improvement in fire management protocols on solar farms, including a case study of Firewatch in action.

What are the Root Causes of Thermal Events on Solar Farms?

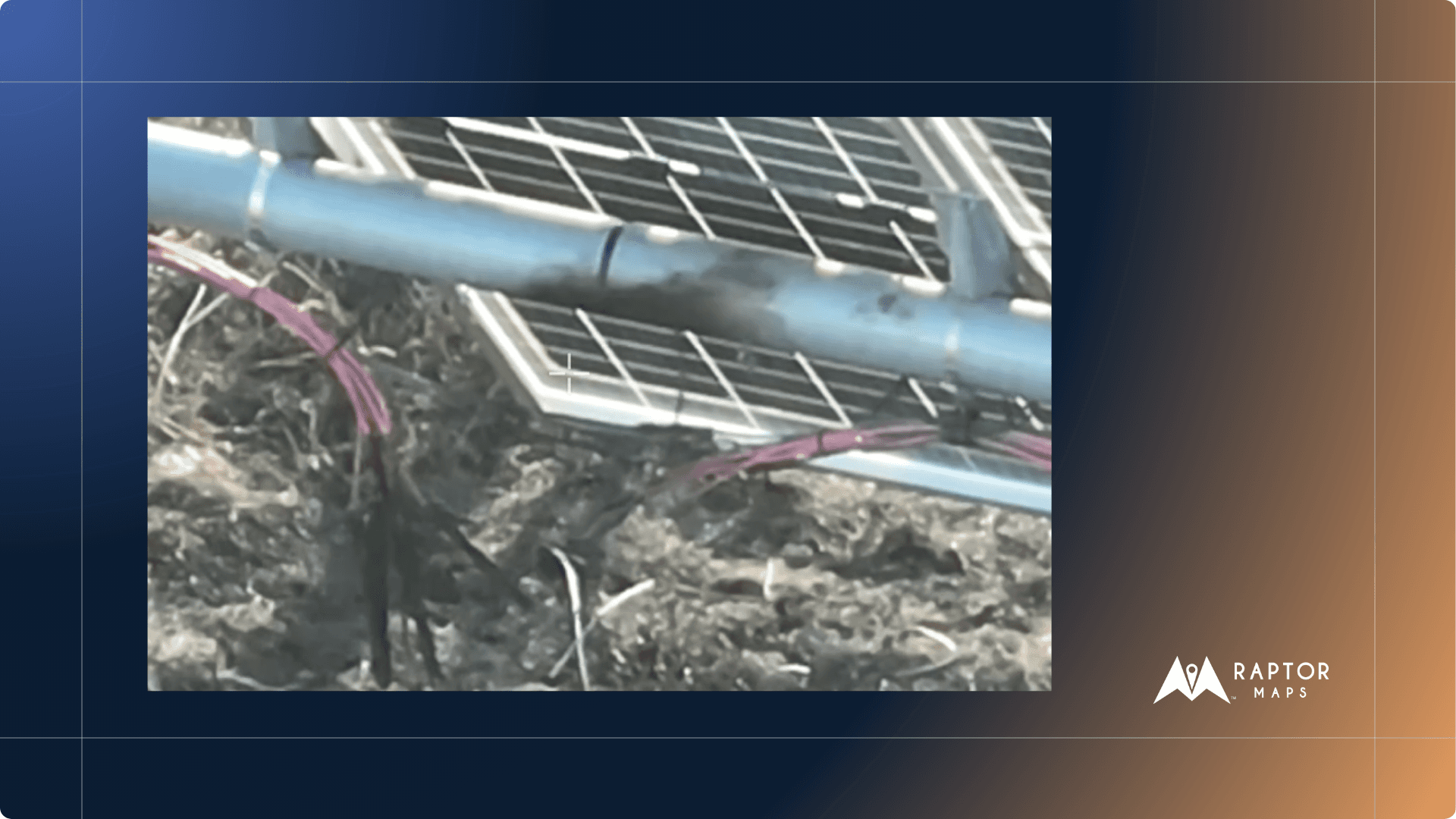

Faulty equipment, either due to poor manufacturing, improper installation, or degradation over time presents ongoing fire risks. Wiring issues, for example, are a major trigger. If connectors aren’t installed properly, loosen over time, or have inadequate crimping, this can create excessive localized heating that can melt insulation and can ignite surrounding vegetation. A recent analysis of over 100,000 solar PV system data points from HelioVolta found that 83% of projects inspected had wiring or connector-driven issues – more than any other PV component.

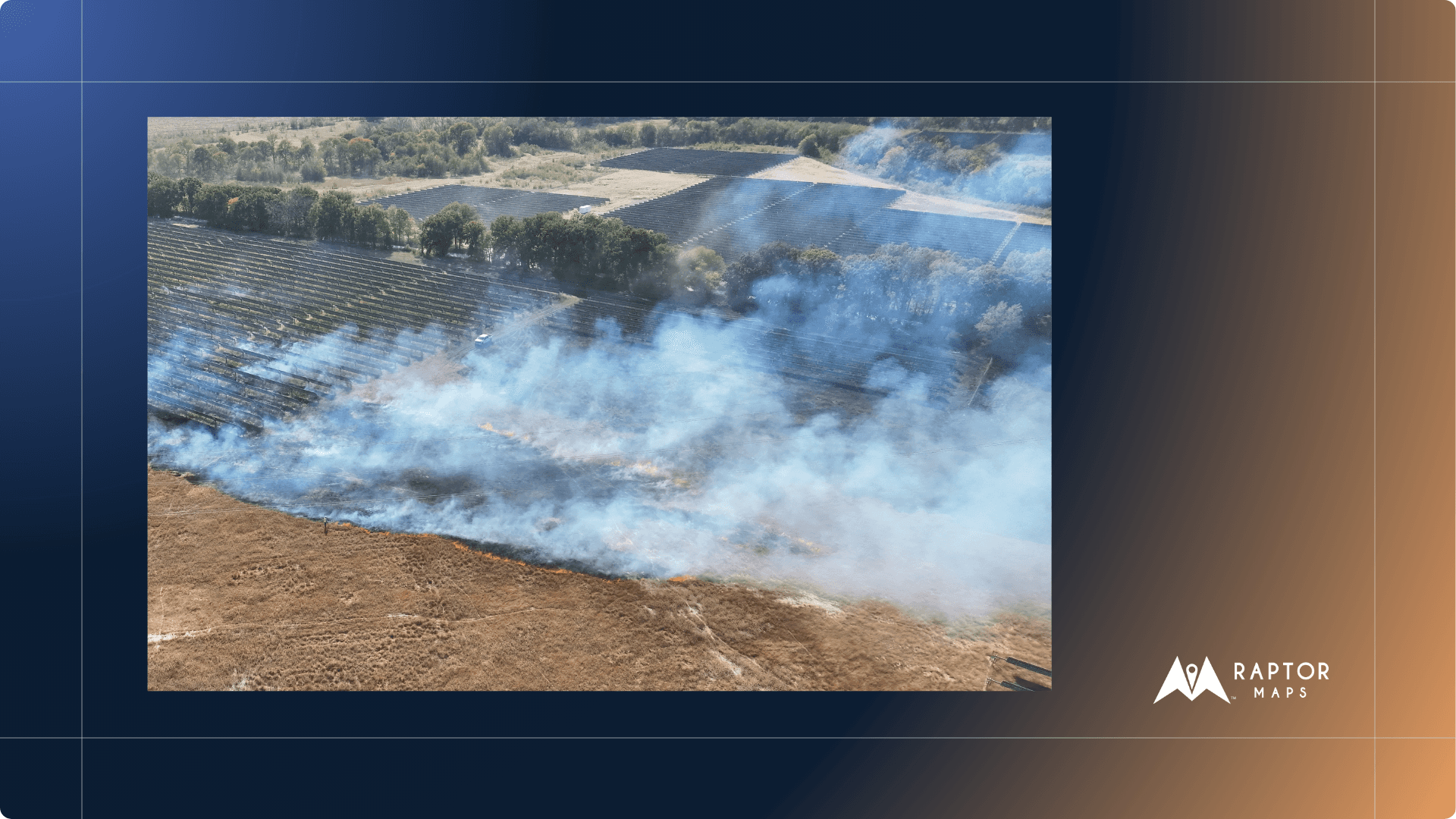

But even without improper installation or component failures, a host of environmental factors can also lead to fires. Vegetation is a notorious source of fire risk. If overgrown, grasses and brush beneath panels can ignite if they come into contact with PV components or are exposed to an electrical fault. Extreme weather can also create conditions that are ripe for thermal events. For example, hailstones can create micro-cracks in module glass, allowing water ingress and creating potential for ground faults that can lead to fires. With extreme weather events increasing in severity and probability, having robust protocols is as important as ever for preventing catastrophic failures on site.

A fire caused by faulty connectors

Conventional Fire Monitoring Approaches - What Isn’t Working?

Despite these extensive sources of fire risk, we often find that current fire mitigation strategies rely on static, infrequent, or reactive measures that struggle to keep large, utility-scale assets adequately prepared to mitigate the risk and impact of fires. Some characteristics of current approaches that we’ve noticed are:

Infrequent Inspections: Traditional annual or semi-annual aerial thermography provides critical data but only offers periodic snapshots. Given that thermal defects can either happen suddenly – perhaps after hail storms or if a connector loosens – or steadily worsen over time, the gap between inspections represents significant unmanaged risk.

Manual Patrolling: Relying on human teams for continuous oversight of vast solar arrays is resource-intensive and inherently slow for detecting nascent thermal risks.

Static Monitoring: Fixed cameras provide limited, often obscured, fields of view. In our experience, these approaches are inadequate for comprehensive site surveillance and early detection because they struggle to capture comprehensive visuals across variable terrain, and, critically, do not offer robust behind-the-panel insights, which is often where fire risk is most prevalent.

Raptor Maps Firewatch: A New Standard in Asset Protection

Our new fire risk inspection protocol is built for two purposes: proactive surveillance to identify early indicators of fires, and rapid reaction if and when fires do occur, which includes and root cause analysis. These inspection protocols are run on Raptor Solar Sentry, our autonomously operated drone-in-a-box solution. Without needing a pilot on-site, the autonomous drone can be programmed to fly routine missions around specific blocks, across the entire site, or launched in immediate response to any thermal events detected.

1. Proactive Surveillance (Pre-Scheduled Missions):

During high-fire risk times of the year, such as deep summer when the land is very dry, proactive fire surveillance involves flying drones at pre-programmed waypoints to detect signs of smoke and fires at predetermined cadences. The drones use high-resolution imagery – both in color and in thermal infrared which detects differences in heat signatures – to scan sites, and if a fire is detected, users and relevant stakeholders are notified immediately.

Through our testing and R&D, we believe that drones are a superior option for ongoing fire-risk detection when compared to static cameras or sensors for a number of reasons. On utility scale sites, sometimes spanning thousands of acres, it is impractical to install the amount of cameras that would be required for comprehensive coverage. Moreover, the ability to scan behind the panel is required to further manage fire risk.

2. Rapid Reaction (On-Demand Response):

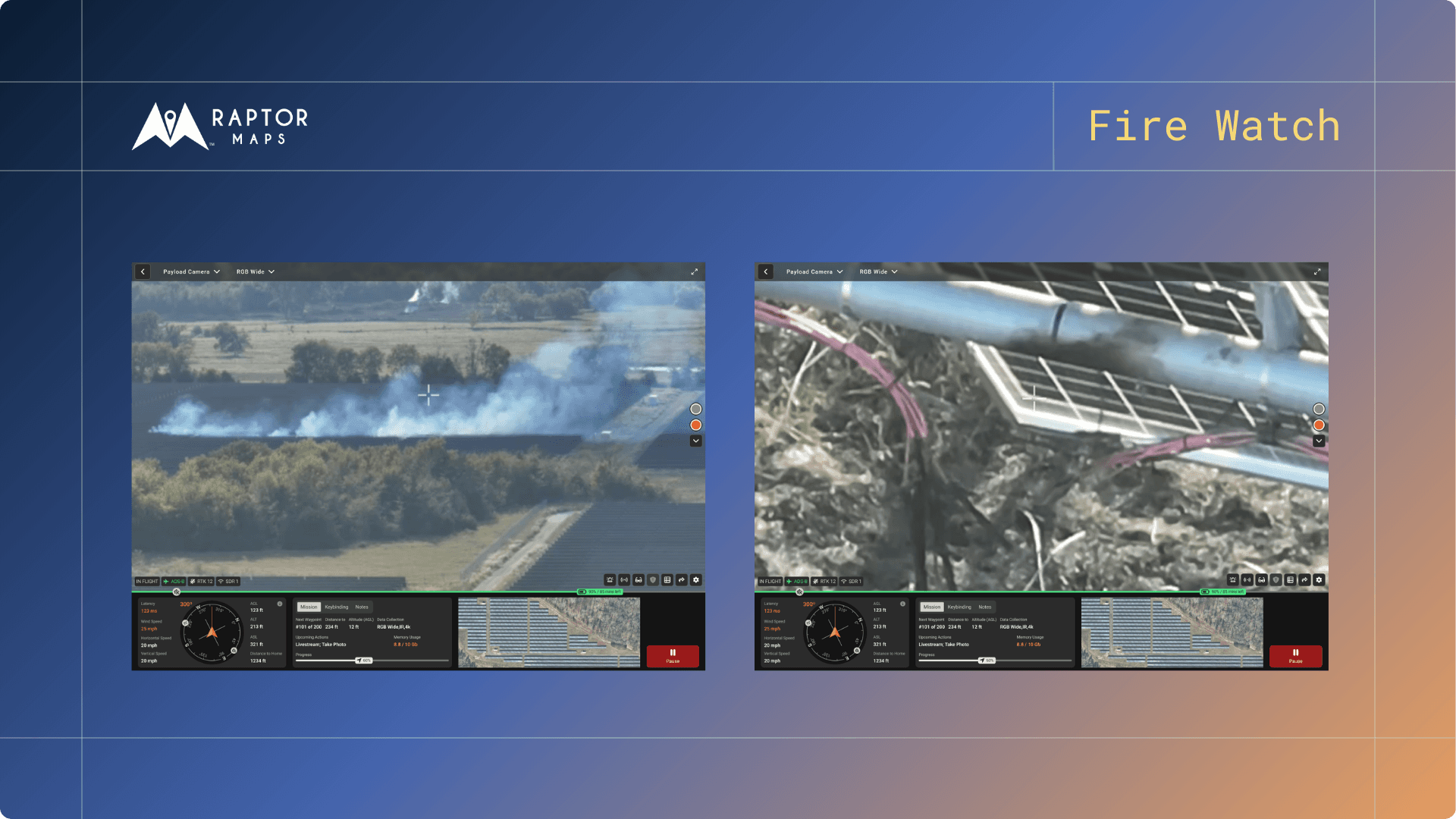

When fire conditions are sensed, either by drone or by a member of the ground team, Raptor Maps’s Remote Operations Center (ROC) is immediately notified and begins a live stream that relevant stakeholders can access, no matter where they are. The live stream offers immediate, real time aerial and visual intelligence within minutes, informing the site team of the fire’s location and movements. This intelligence is immediately actionable, augmenting emergency ground operations in response to the thermal event. After the fire, a follow-up drone flight will give a detailed assessment of the impacted area.

A view of a fire from the 'live stream cockpit' of a remotely operated drone

Case Study

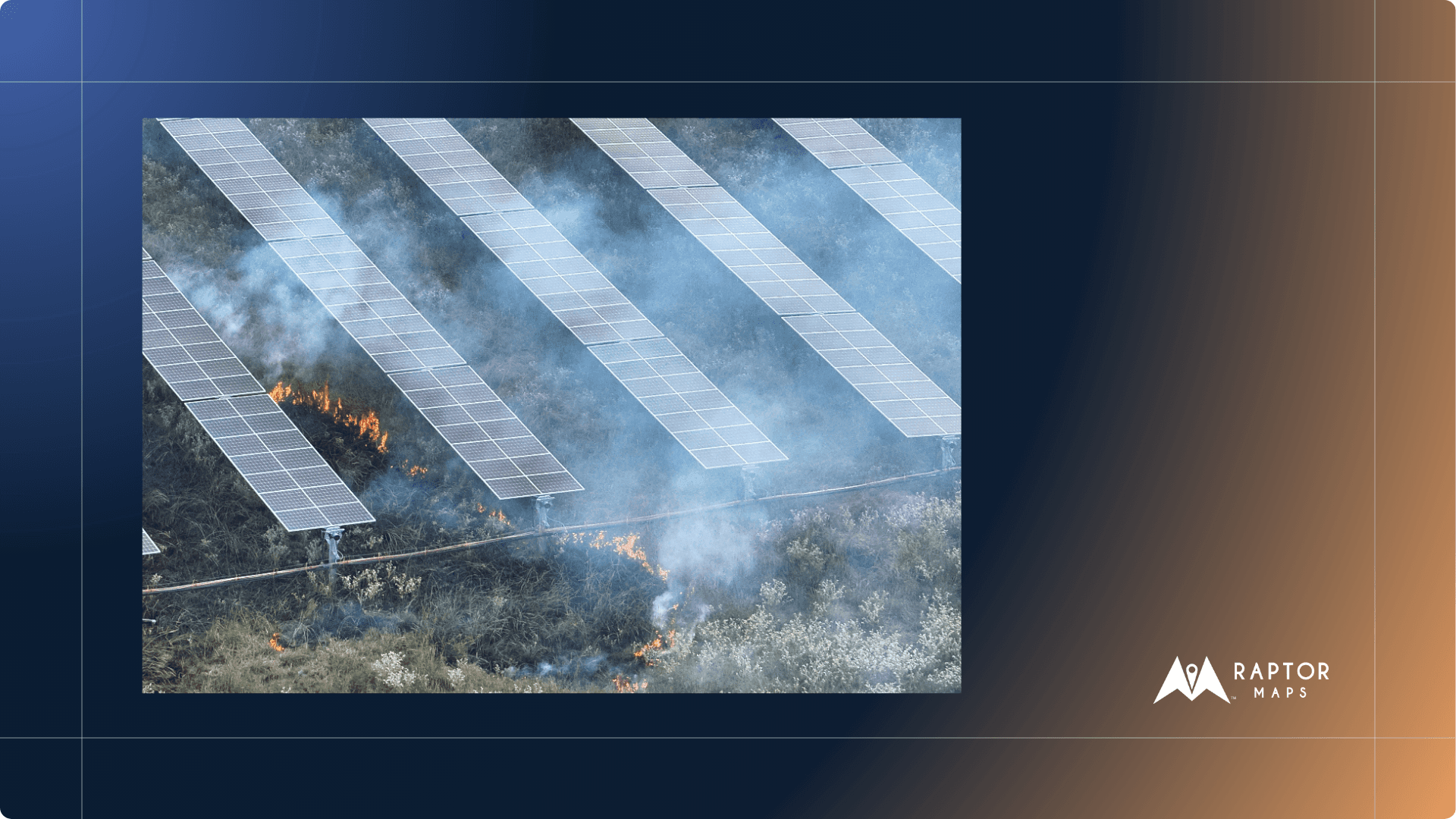

On a >250 MW utility scale site in ERCOT, during a routine Raptor Solar Sentry inspection, a Raptor Maps’ Remote Operations Center (ROC) operator noticed a fire. It was after 5pm, when all workers were off the site.

The site’s SCADA system had not yet picked up on the active fire; the site team was not aware of the situation until members of Raptor Maps’ ROC alerted them upon seeing the fire.

The immediate availability of aerial intelligence was important for ensuring safety of the site team, and for communicating precisely with local first responders.

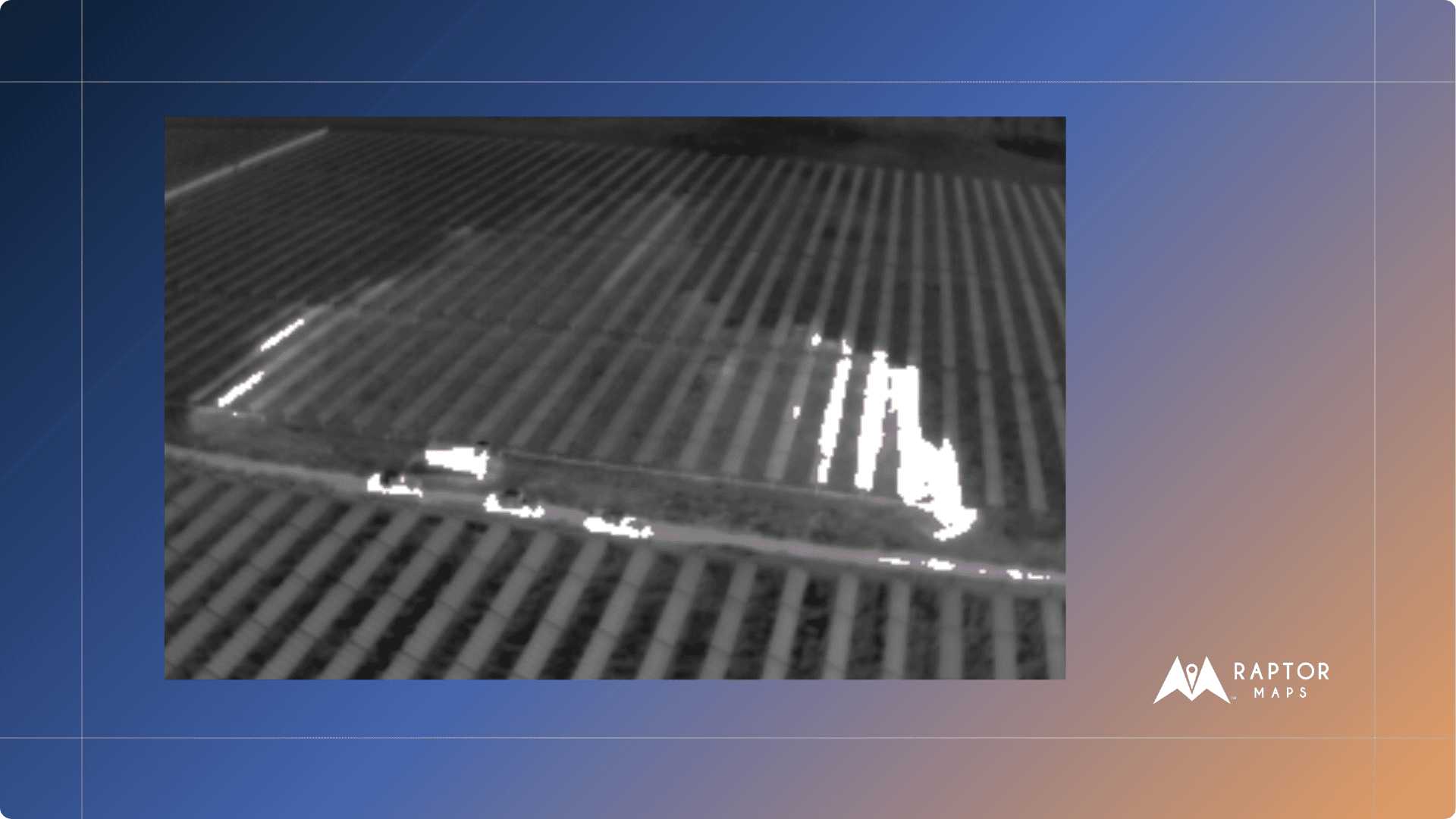

Once the fire was resolved, Raptor Maps flew follow up inspections to determine root causes of the fire and to document the extent of the damage for remediation prioritization and to generate a digitized system of record for insurance documentation.

Thermal imagery of the damaged area informs first responders where to target and technicians where remediation needs to occur

Interested in Fire Watch for Your Assets?

If you are interested in how autonomous drones can support your fire risk management, we’d love to hear from you. Click the contact us link below and one of our fire-risk experts will follow up to help deep dive on best practices and how your team can leverage technology to build a world-class fire risk management protocol.

Thermal imagery of the damaged area informs first responders where to target and technicians where remediation needs to occur

Next steps

From the civil engineering on your site down to the wiring on the back of your panels, the Raptor Solar platform provides you detailed, up-to-date data on the conditions and performance of your solar fleet so that your team has the intel they need to do their jobs effectively, quickly, and safely.

More

Product Updates

July 2025 Update: Nighttime Inspections and Capacity Testing Inspection Types Added

Posted on 7/28/25

Learn More

Custom Temperature Delta Analysis, Livestream Dashboard, and More: June Product Updates

Posted on 6/25/25

Learn More

Spring 2025 Product Updates: Livestream, Expanded Inspection Order Menu, and More

Posted on 3/27/25

Learn More